- Research Projects

Summary of Nextgreen’s R&D Projects

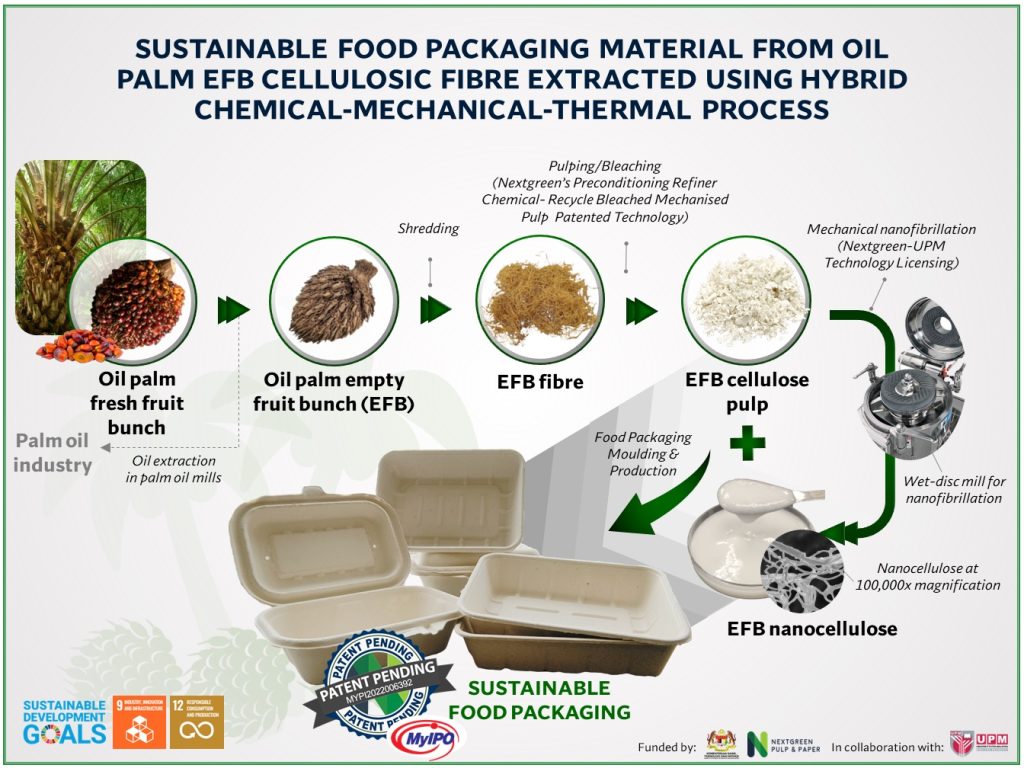

Sustainable food packaging materials from EFB pulp & nanocellulose

As a pulp producer from EFB, Nextgreen aims to create a green, environmentally friendly, and biodegradable food packaging product, which would support the Malaysian government’s goal of reducing the use of single-use plastics. This RM4.4 million project, started in July 2019 and ended in November 2022, and was co-funded by the Ministry of Science, Technology, and Innovation (MOSTI) and Nextgreen. Together with Universiti Putra Malaysia (UPM), Nextgreen utilised the oil palm EFB as a main raw material for the development of sustainable food packaging.

This MOSTI-Nextgreen-UPM collaboration is aimed at maximising the potential of nanocellulose which is made from the EFB as an advanced nanomaterial for enhancing the mechanical and water barrier properties of EFB-based food packaging. Aligned with Nextgreen’s mission of producing a green product with zero waste that can benefit stakeholders and society as a whole, the Social Return on Investment (SROI) forecast indicates that Nextgreen will achieve its goals of transforming stakeholders' lives and conditions, not only economically, but also socially and environmentally.

This MOSTI-Nextgreen-UPM collaboration is aimed at maximising the potential of nanocellulose which is made from the EFB as an advanced nanomaterial for enhancing the mechanical and water barrier properties of EFB-based food packaging. Aligned with Nextgreen’s mission of producing a green product with zero waste that can benefit stakeholders and society as a whole, the Social Return on Investment (SROI) forecast indicates that Nextgreen will achieve its goals of transforming stakeholders' lives and conditions, not only economically, but also socially and environmentally.

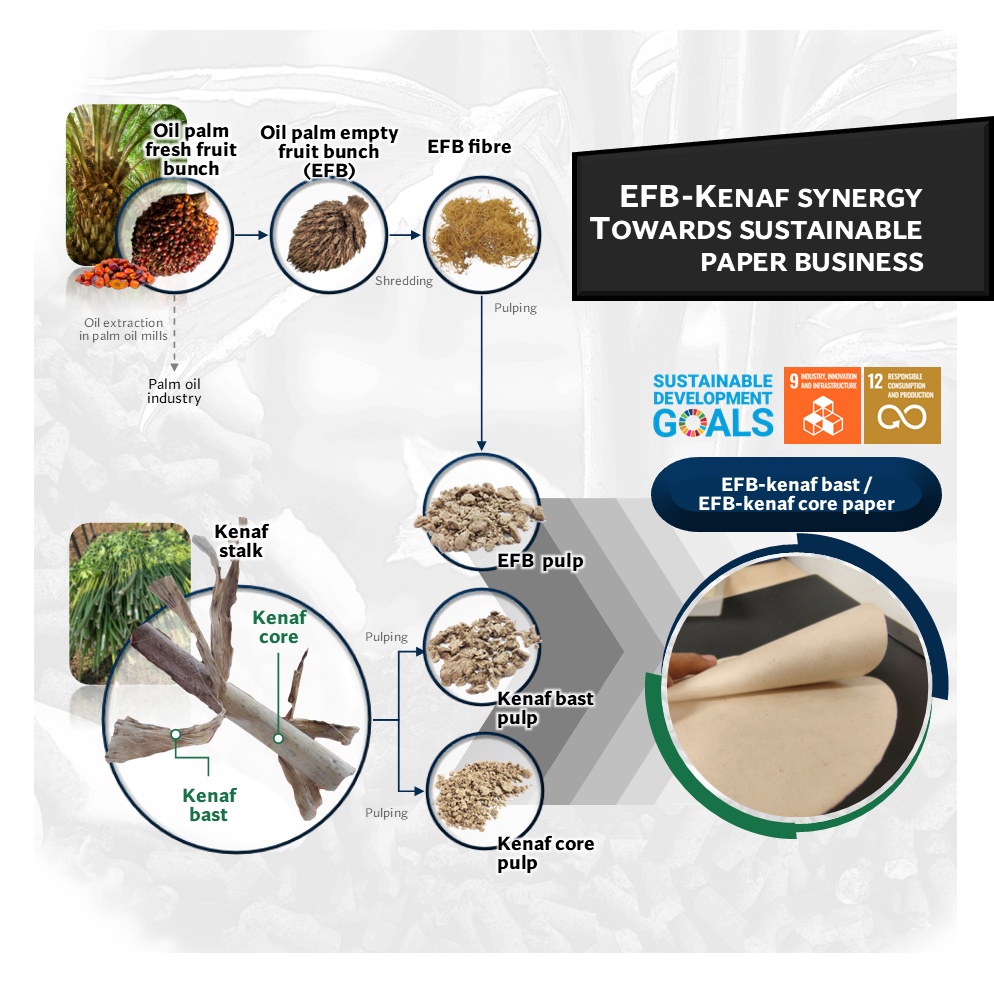

Paper production from empty fruit bunches (EFB) and kenaf

Nextgreen in collaboration with Universiti Teknologi MARA (UiTM) aims to promote green technology for pulp and paper making by using a non-toxic process that may contribute to less energy and water consumption. This three-year project commenced on August 2021, and anticipates the reduction of wood fibers dependency for paper making process by considering the abundant raw materials in the form of EFB and blending it with the fast-growing kenaf whole stem fibers. Through the optimisation of the EFB-kenaf ratio, we could achieve the enhanced production efficiency of the EFB/kenaf papers that meets the ISO 187:1990 certification, the standard for pulp and paper manufacturing.

Conversion of black liquor to lignin for adhesive production

Nextgreen is working with a group of Shaanxi University of Science and Technology (SUST), China researchers since 2018 to develop an environmentally and industrially friendly process to extract lignin from black liquor, which can be used to produce bio-adhesives. This project concluded in 2022 and foresees the promising potential of black liquor, a pulp and paper mill-generated waste as a feedstock for lignin production. The use of black liquor derived lignin to replace harmful precursors in adhesive production such as formaldehyde and petroleum-derived phenol promotes responsible and sustainable production in terms of the efficient use of renewable and environment-friendly resources.

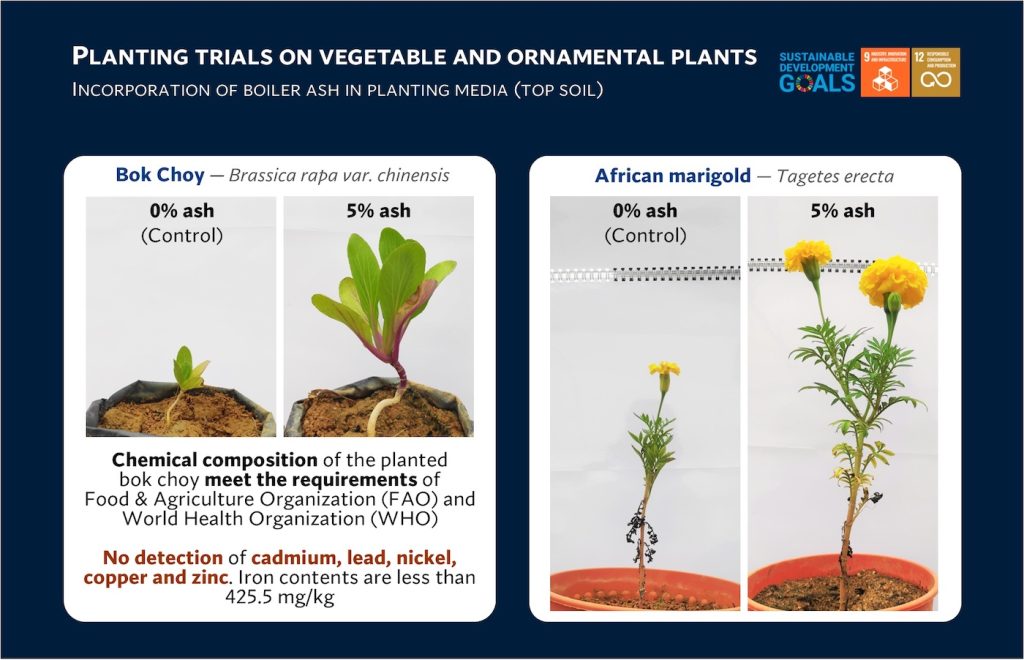

Utilisation of EFB boiler ash as soil conditioner for planting

NGPP uses EFB as a combustion material for the boiler. The ash generated could be used for value-added purposes as EFB ashes often contained high alkalinity and various nutrient contents that can be good for soil improvement and improving crop growth. This six-month project observed bigger, taller and more leaves number in both vegetable and ornamental plants. In addition, the bok choy chemical composition meets the requirements of Food & Agriculture Organization (FAO) and World Health Organization (WHO) indicating safe use of the EFB ash as part of planting medium or soil conditioner.

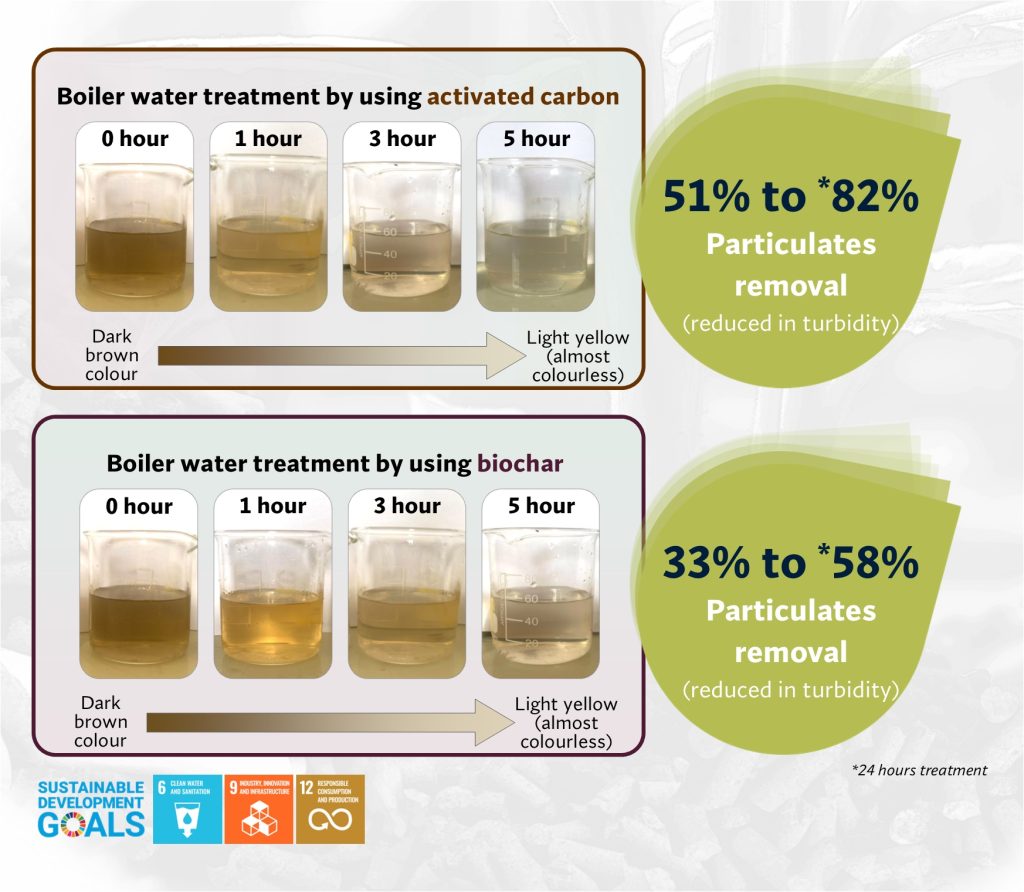

Biochar & activated carbon for boiler’s discharged water treatment

Nextgreen uses a closed-loop wet scrubber water system as an effective air pollution control device to remove particles and/or gases from the boilers, as well as to prevent a variety of pollutants from being released into the atmosphere. The Nextgreen R&D team conducted a water discharge treatment experiment to evaluate potential utilisation of bioadsorbent derived from biomass — activated carbon and biochar to remove contaminants in the discharged boiler water. The lab scale findings suggest up to 82% particulates removal indicating potential implementation of these bioadsorbent in the wastewater treatment system. The treated water could also be reused in the boiler wet-scrubber system, enhancing the efficient use of resources in Nextgreen’s mills operation.